Concentrating Solar Thermal Power with point focus Fresnel lens and reflector.

A bifacial thermal absorber is used. 50% of the light falls on the front of the absorber. The rest is reflected to the back of the absorber with a mirror. The input aperture is 1m2, the radius of the absorber is 10mm, the average concentration level is 3087 with an optical geometric efficiency of 97% (excluding reflection/transmission/tip losses).

If only the front surface is used, then the optical efficiency drops to 87.3% for an average concentration level of 3080 (run fresnelx w1000 g2500 l10000 s1000 c870:9.5 r0). About 6% (after subtracting the reflective loss due to the mirror) more energy can be extracted by using both surfaces.

The heat from an array of these absorbers will be stored in graphite pebbles. The heat from the storage system will be used to produce mechanical work (Rankine, Ericsson, Stirling, Scroll, Brayton and rotary engines). Mechanical compressor can use this mechanical energy for cooling or heating purpose. The mechanical energy can be converted directly to AC electricity with a 3-phase induction motor (thus avoiding the cost of using an inverter).

The higher the difference in temperature between the heat source and the heat sink, the greater the theoretical efficiency. Convection and conduction losses are insignificant at high concentration ratio. Since practical selective coatings only work up to 800K, they are irrelevant for high temperature concentrators.

Simulation

run 'fresnelx w1000 g2500 l1000 s100 r51 c50:10 c97:10' first to calculate concentration levels

fresnelx w1000 g2500 l1000 s100 r51 13656 2570 v.2

777.37W/m2 refractive index at 589.2nm(1.492) m(20), eff(99.990%)

SunHalfAngle(0.26657o)

Total input energy 777 Watts

Acrylic Fresnel Lens Width 1000mm x 0.150mm, Area 1.00m2,

Focal Length 1000mm (f/1.000), 2500 grooves

Slice Radius Power Tot Tot QEff Ix Ax Area UV BlueGreen Red NIR IR

390 492 622 760 1110 4000

mm W W % % cm2 % % % % % %

Cell 1 Concentration Level 3656.0x, distance from lens 983.5mm, 0.98f,

radius 9.3mm

0 0.2 17.9 18 2 74 182721 182721 0 4 7 0 3 87 0

1 0.4 17.1 35 4 73 58391 89474 0 4 7 0 3 85 0

2 0.6 17.0 52 7 73 34849 59129 0 4 7 0 5 84 0

3 0.8 17.8 70 9 75 26081 44670 0 4 7 0 6 84 0

4 1.0 18.4 88 11 76 20945 36129 0 4 7 0 7 83 0

5 1.2 18.7 107 14 78 17417 30411 0 4 7 0 8 82 0

6 1.4 19.0 126 16 77 14962 26313 0 4 7 0 9 80 0

7 1.6 17.3 143 18 68 11800 22911 0 4 8 0 12 69 7

8 1.8 17.9 161 21 57 10760 20361 0 4 8 0 14 53 21

9 2.0 19.5 181 23 46 10517 18491 0 4 8 0 15 39 35

10 2.2 19.5 200 26 39 9482 16927 0 4 8 0 17 29 42

11 2.4 15.3 215 28 40 6819 15313 0 5 11 0 27 20 38

12 2.6 17.4 233 30 34 7105 14098 0 4 11 0 30 10 45

13 2.8 17.7 250 32 32 6701 13079 0 4 11 0 28 9 48

14 3.0 14.0 264 34 38 4928 12029 0 5 16 0 33 10 36

15 3.2 12.3 277 36 41 4066 11065 0 6 19 0 35 11 29

16 3.4 11.0 288 37 45 3400 10189 0 6 24 1 38 11 21

17 3.6 10.8 298 38 45 3152 9429 0 6 27 2 37 10 18

18 3.8 10.9 309 40 45 3010 8771 0 6 30 2 36 9 17

19 4.0 11.0 320 41 45 2887 8198 0 6 35 3 33 8 15

20 4.2 11.4 332 43 44 2846 7700 0 6 40 3 30 8 14

21 4.4 12.4 344 44 44 2950 7278 0 5 48 4 25 6 12

22 4.6 17.8 362 47 44 4041 7003 0 3 58 7 18 6 9

23 4.8 26.0 388 50 49 5661 6893 0 1 33 23 21 13 9

24 5.0 22.7 411 53 50 4751 6725 0 1 26 25 23 15 10

25 5.2 20.9 432 56 50 4197 6535 0 1 22 27 24 15 11

26 5.4 19.8 451 58 50 3820 6337 0 1 20 28 24 16 11

27 5.6 18.9 470 60 51 3508 6139 0 1 18 29 24 16 12

28 5.8 17.8 488 63 51 3206 5940 0 1 16 30 24 17 12

29 6.0 17.1 505 65 51 2964 5745 0 1 15 31 24 17 12

30 6.2 16.5 522 67 50 2770 5556 0 1 14 31 24 17 13

31 6.4 16.0 538 69 51 2593 5374 0 1 13 32 24 17 13

32 6.6 15.3 553 71 51 2411 5197 0 1 11 33 24 17 13

33 6.8 14.9 568 73 51 2282 5028 0 1 11 34 23 18 13

34 7.0 14.4 582 75 51 2135 4865 0 1 10 35 23 18 13

35 7.2 14.0 596 77 51 2020 4709 0 1 9 36 22 19 13

36 7.4 13.5 610 78 52 1891 4559 0 1 8 38 21 19 13

37 7.6 13.1 623 80 52 1788 4415 0 1 7 39 20 20 12

38 7.8 12.7 635 82 52 1686 4277 0 1 6 41 19 20 12

39 8.0 12.3 648 83 53 1594 4144 0 1 5 44 18 21 12

40 8.2 11.9 660 85 53 1507 4017 0 1 4 44 18 21 12

41 8.4 11.6 671 86 53 1428 3896 0 1 3 44 18 22 11

42 8.6 11.3 683 88 53 1360 3779 0 1 3 45 18 22 11

43 8.8 11.0 694 89 53 1298 3667 0 1 2 45 18 22 12

44 9.0 10.8 704 91 54 1239 3561 0 1 1 45 19 23 12

45 9.2 10.5 715 92 54 1181 3458 0 1 0 45 19 23 12

46 9.4 10.2 725 93 54 1126 3360 0 1 0 45 19 23 12

47 9.6 9.9 735 95 54 1071 3266 0 1 0 44 20 24 11

48 9.8 9.6 745 96 55 1018 3175 0 1 0 44 20 24 11

49 10.0 9.4 754 97 55 971 3088 0 1 0 43 20 25 11

run 'fresnelx w1000 g2500 l1000 s100 r51 13656 26200' to calculate the radius and placement of the mirror. 6200 = (1000 / (1000 - (1041.9 + 983.5) / 2)) ^ 2

Tracking Error

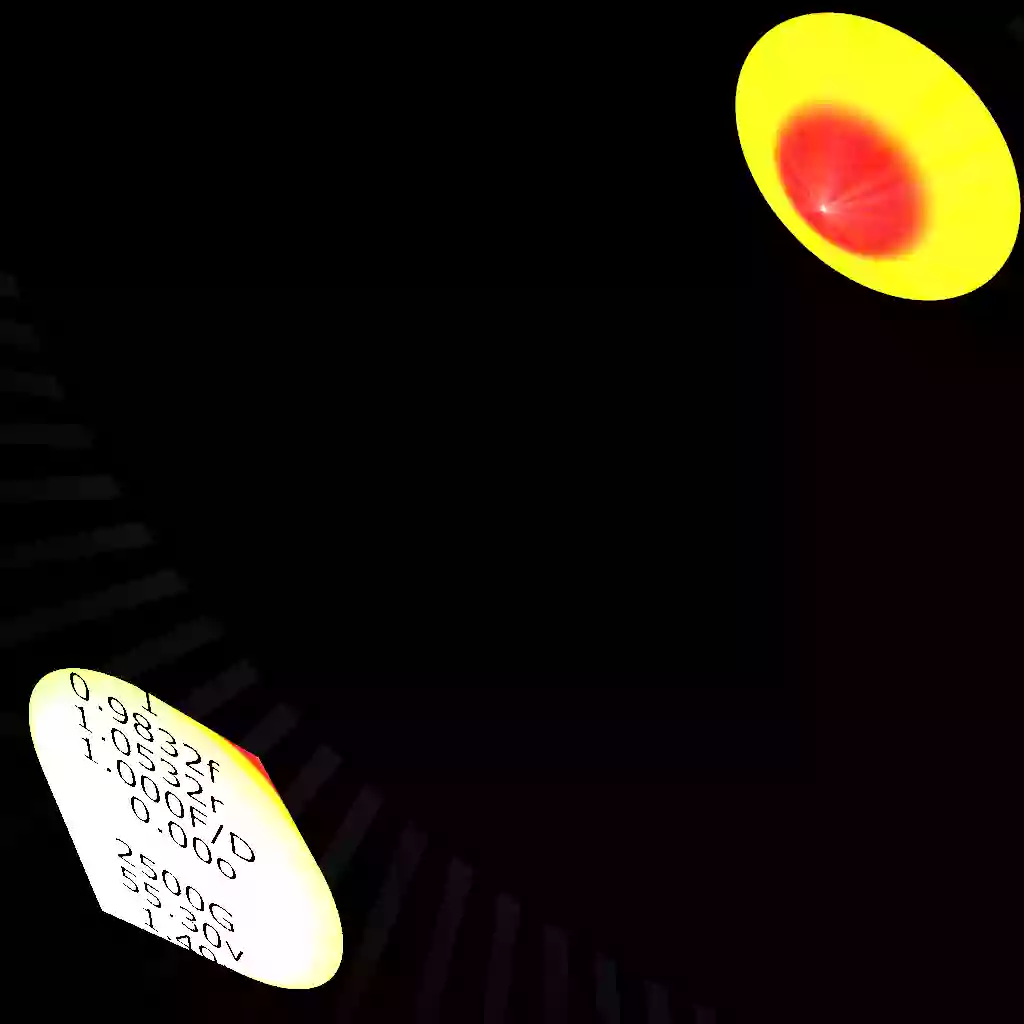

Visualisation of tracking error from 0 to 0.5 degree in step of 0.01 degree. The absorber is a double ended cone with a radius of 10mm and end to end height of 10mm. The heat transfer liquid will enter from the front center and exit at the back center. The image at the top right corner is the reflection of the back of the cone. The average concentration level over the entire absorber is 1380 = 1e6 * 0.97 / (2 * pi * 10 * sqrt(10^2 + 5^2))

Cost Calculations

Links

StarRotor (Brayton Cycle). 45-60% efficiency. Have working compressor at 80% efficiency.

Stirling Energy Systems. SunCatcher, 25kW solar dish Stirling Cycle. 31% efficiency.

Capstone Turbine. Externally fired 65kW C65 Capstone Microturbine (Brayton Cycle). 29% efficiency.

GrafTech. Synthetic graphite for thermal energy storage.

|

Last updated: Sun, 24 Jan 2021 22:03:08 GMT |