Solar Pyrolysis production of biochar, oil, and gas from organic matter with Zero Emission

What?

Solar Pyrolysis uses high temperatures and pressure in a low oxygen environment to convert organic matter into char, oil, and gas. Earth uses the same process to make coal, crude oil, and gas over a timescale of millions of years.

Why?

It converts material normally considered as waste and pollution into a more stable material that is more valued and has higher calorific value. These "waste" includes wood waste, farm waste, food waste, sewage sludge, putrescible waste from landfill, shredder floc, plastics, and car tires. Conventional incinerators, pyrolysis, gasification, hydrothermal liquefaction, and plasma gasification uses a non-renewable source of energy, burn some of the biomass for fuel and generates more pollution. Solar Pyrolysis uses sunlight, captures all emissions and creates a higher value product.

How?

Solar Pyrolysis uses paraboloid mirrors to focus sunlight into a clear hollow fused quartz sphere containing the biomass. The high temperature decomposes the biomass. The high pressure extracts more solid carbon from the biomass. The catalytic hydrothermal liquefaction step converts heavier hydrocarbons to lighter ones. Fractional distillation columns will then distill the oil and gas. The syngas can be used to generate electricity with fuel cells or cryogenically liquified for use later.

Where?

Where there is bright sunlight, plentiful waste, and demand for char, oil, and gas.

When?

Yesterday.

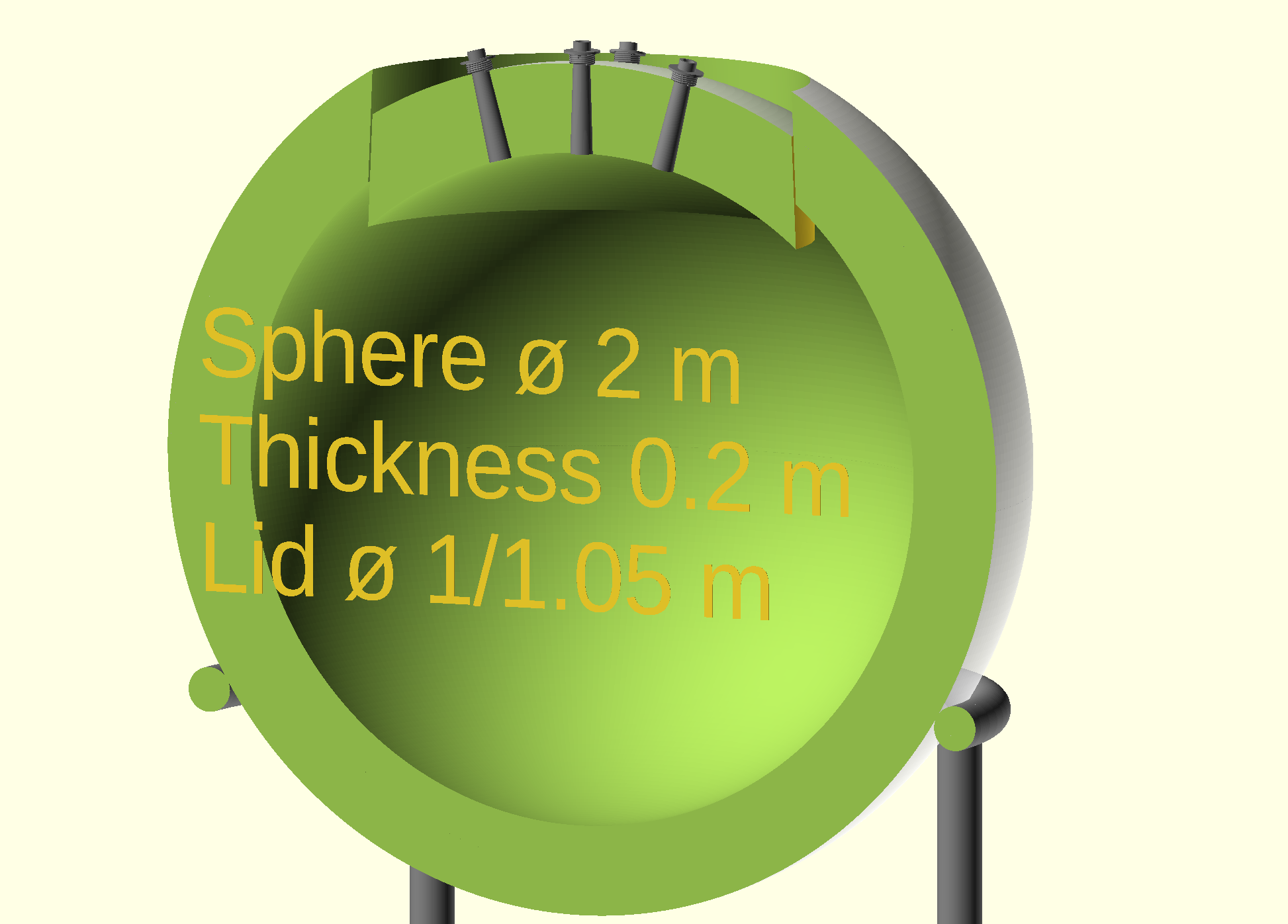

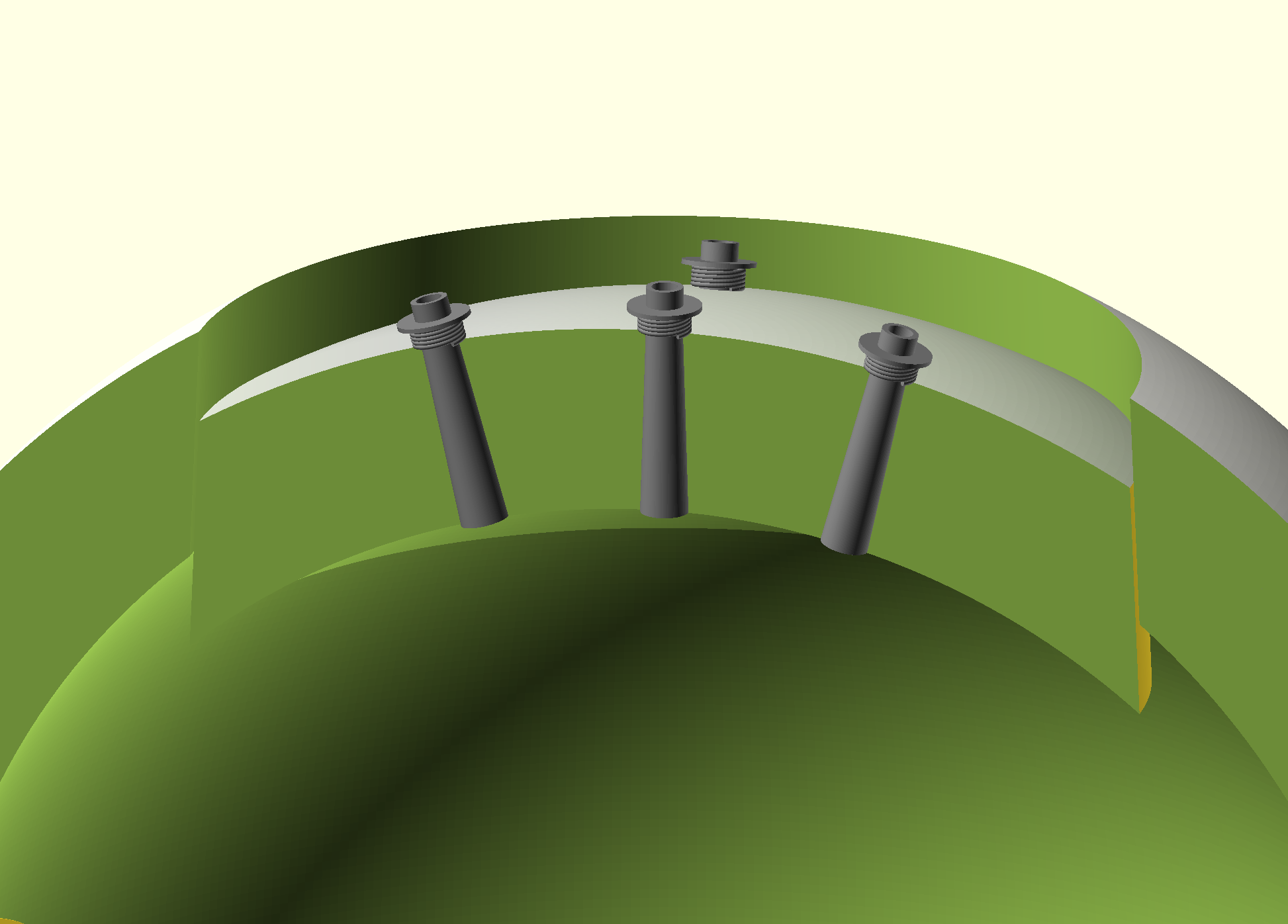

Pyrolysis Distillation Sphere

2000mm diameter clear hollow fused quartz sphere with a thickness of 200mm. The sphere has a 1000mm diameter tapered hole at the top that is 50mm wider on the inner side. The tapered plug is always inside the sphere and cannot be removed. Plug that consists of more than one piece can be removed. The plug has five 40mm diameter tapered holes that are wider by 6mm on the inside. The middle one is the outlet. The others can be used to monitor temperature or pressure or sampling of material inside. The holes also function as attachment points. The top of the spheres should be shielded from the rain and hailstones.

Cut out of sphere |

Detail of sphere plug |

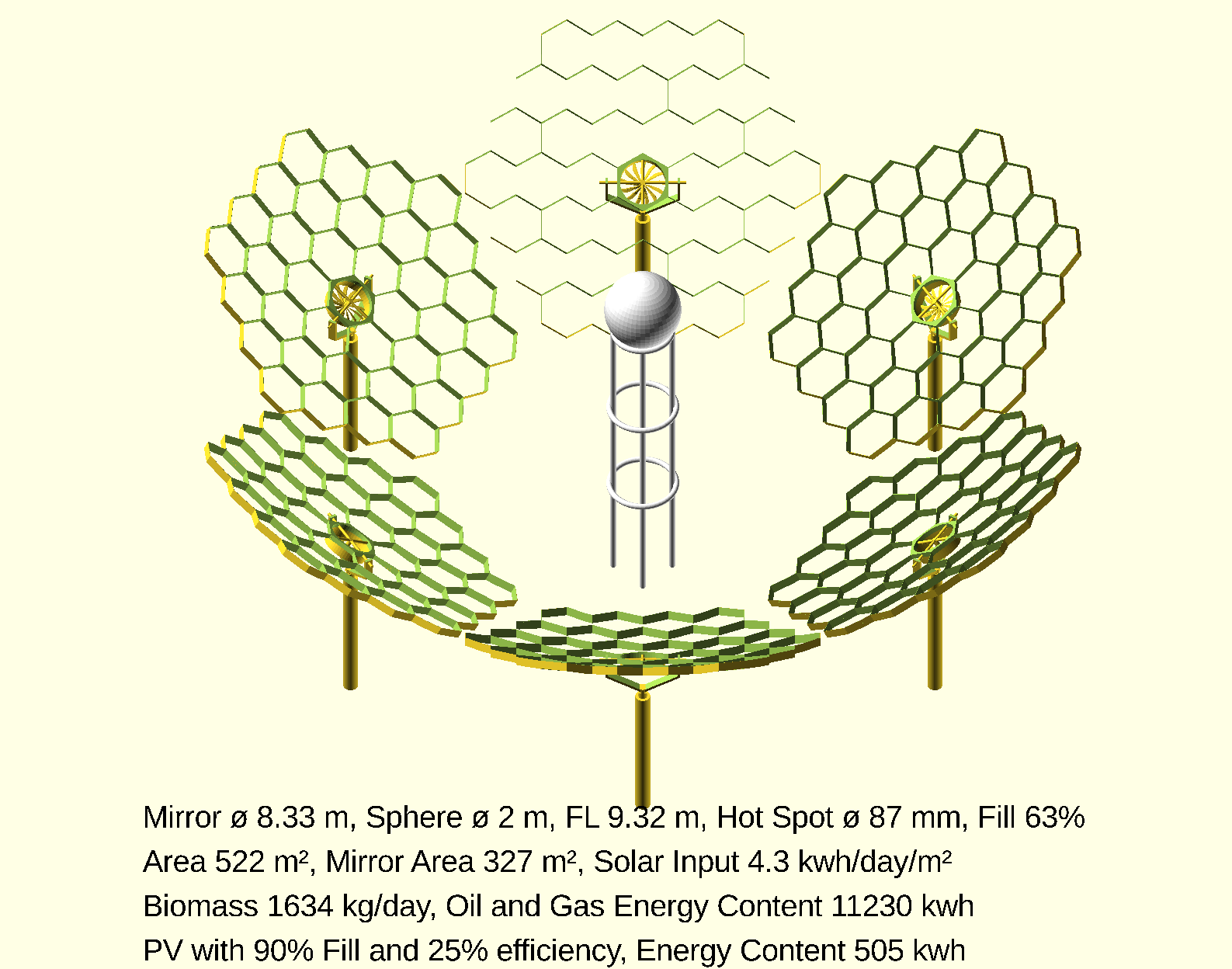

Paraboloid Mirrors

Each paraboloid mirror is under central computer control with two-axis tracking. Reflective mylar sheets are stretched over the hexagonal aluminum struts.

Mirror Cross Section |

8.5 m diameter mirrors array |

Solar Field

The sphere at each set of mirrors accepts biomass. The vapors are directed to the fractional distillation column. The heating of the sphere will be paused if its temperature exceeds 1200°c.

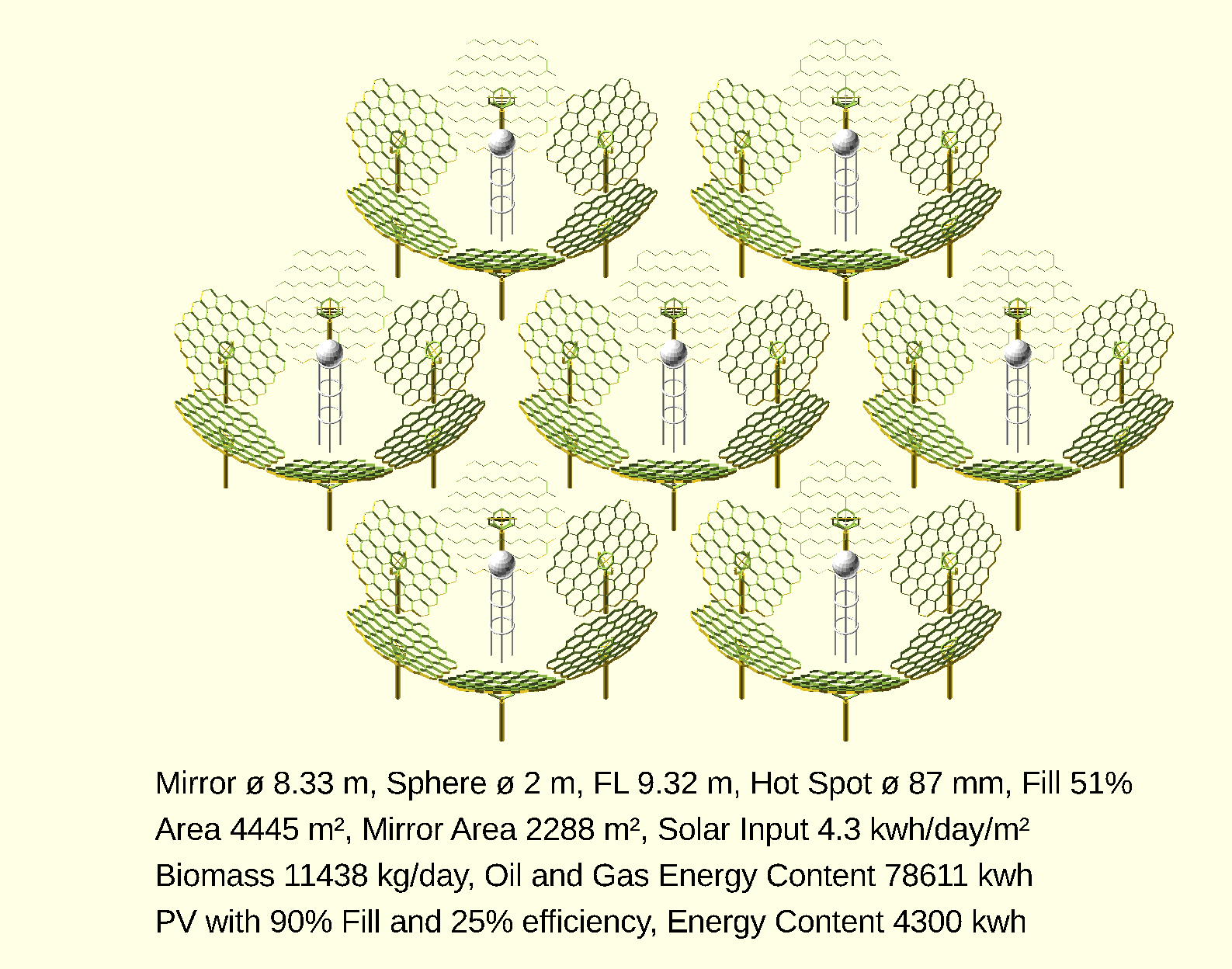

Small Field |

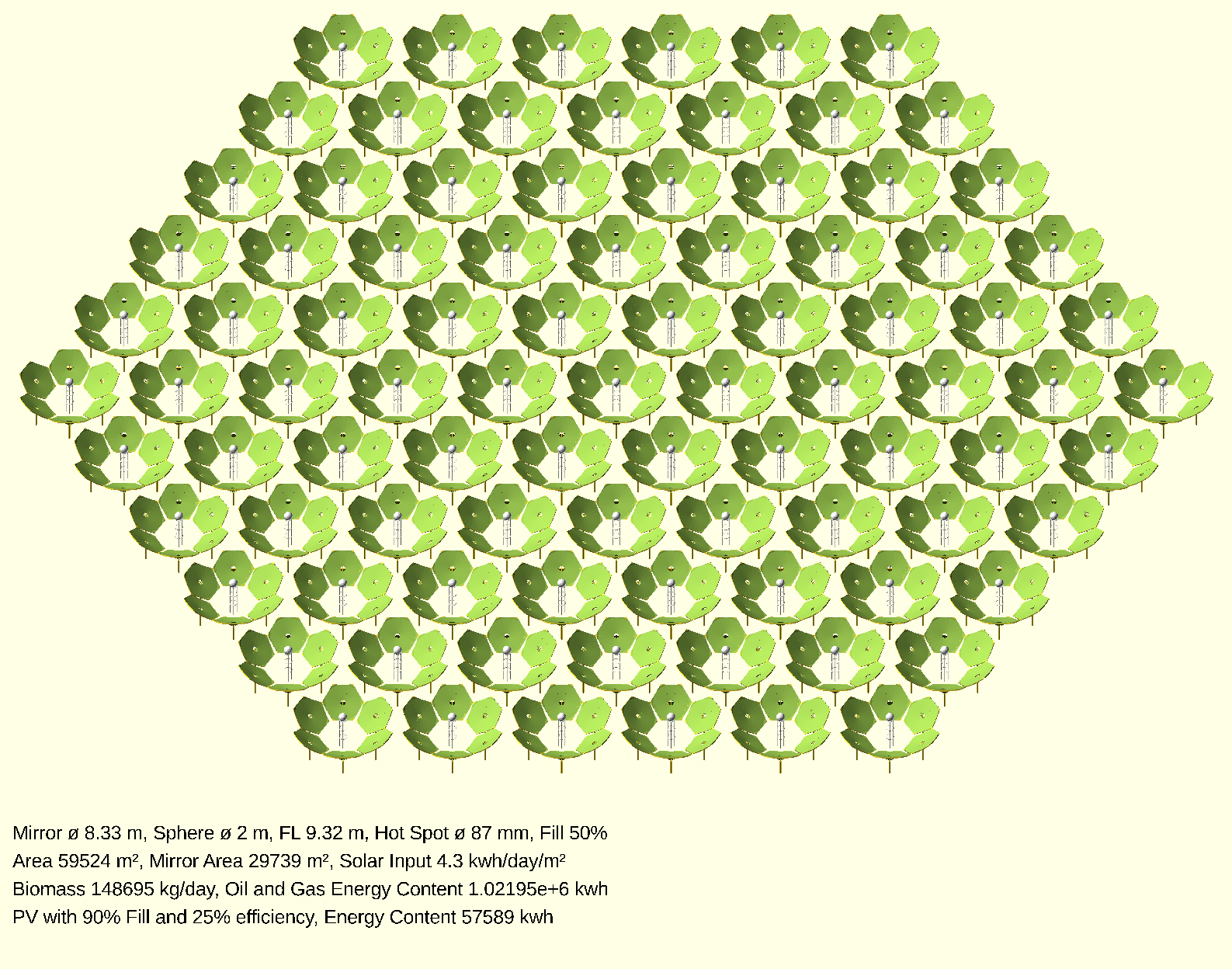

Large Field |

Operation

Gently fill the sphere with biomass, there is no need to dry or chip the biomass, seal it. Remove the oxygen and pressurize it with H₂ to 10 Bars. Point all mirrors at the sphere and continually adjust to focusing on the sphere. Each sphere outlet has a pressure relief valve that is set at 20 Bars. The H₂, CO, CO₂, and C₁-C₄ hydrocarbons from the fractional distillation column can be used to generate electricity using SOFC (Solid oxide fuel cells). A micro gas turbine will use the hot exhaust (H₂, H₂O, CO, and CO₂) to generate electricity. The exhaust from the MGT is sent to the hydrothermal liquefaction chamber or spheres. If excess fuel is available to power the fuel cells, a Hydrothermal liquefaction step can be put between the spheres and the fractional distillation column, using electricity.

Emptying the Sphere

The size and number of mirrors are sized so that the process is completed by the time the sun goes down. As soon as the sun goes down, vent all the vapor to the distillation column until the pressure drops to atmospheric pressure, then disconnect. After the sphere is cooled, empty the sphere, fill it with biomass, close it. Remove oxygen from the sphere, then pressurize the sphere to 10 Bars with H₂.

Cryogenic Distillation

If the vapors from the fractional distillation column cannot be used immediately, then it will be liquified with a cryogenic cooling system. When more fuel is needed for the SOFC, the liquid fuel can be expanded with the heat from the exhaust of the MGT, improving the efficiency of the MGT.

Hazardous and Landfill Waste Volume Reduction

Non-recyclable or hazardous waste such as asbestos-contaminated materials, copper chrome arsenate treated timber, PFAS-contaminated soil, chlorinated hydrocarbons, fiberglass, printed circuit boards, can be distilled to isolate the hazardous material.

Biomass Processing Centers

These centers will buy unwanted biomass at the same price as coal and sell the char, oil, and gas produced. The waste collection policy is set so that the majority of people benefit from it. The profit will be used to fund centers in other areas and local projects. People will start seeing wastes as valuable resources.

Code of Conduct

Only matter considered as waste, not recyclable, and local should be used as feedstock. The best 50% of the char (carbon) produced must be locked up by using it with compost to enrich soils.

Contact

Contact Philip Wong at ioserver@ioserver.com with any corrections, comments or critique of this proposal.

Costing spreadsheet for Solar Pyrolysis

Links

Extracting energy from wind and PV at the same time

Effect of high-pressure on pine sawdust pyrolysis: Products distribution and characteristics

The Role of Pressure in the Heat of Pyrolysis of a Lignocellulosic Biomass

Problems and Opportunities for Solar Energy in Biomass, Pyrolysis, and Gasification

Solar Biomass Pyrolysis with the Linear Mirror II

Modelling and evaluating a solar pyrolysis system

Characterization of solar fuels obtained from beechwood solar pyrolysis

Solar-Thermal Pyrolysis of Mallee Wood at High Temperatures

Concentration with a Parabolic Reflector

Pyrolysis: A Sustainable Way to Generate Energy from Waste

Combustion and Gasification rates of Lignocellulosic Chars

|

Last updated: Thu, 16 Jun 2022 08:02:04 GMT |